How to Choose the Right Expansion Joint for Your Project

Expansion joints are critical components in construction, designed to absorb movement and prevent structural damage. Whether you’re working on a building, bridge, pipeline, or another structure, selecting the right expansion joint is crucial for the project’s success. This article provides a comprehensive guide on how to choose the right expansion joint for your project, considering factors such as material, size, application, and environmental conditions.

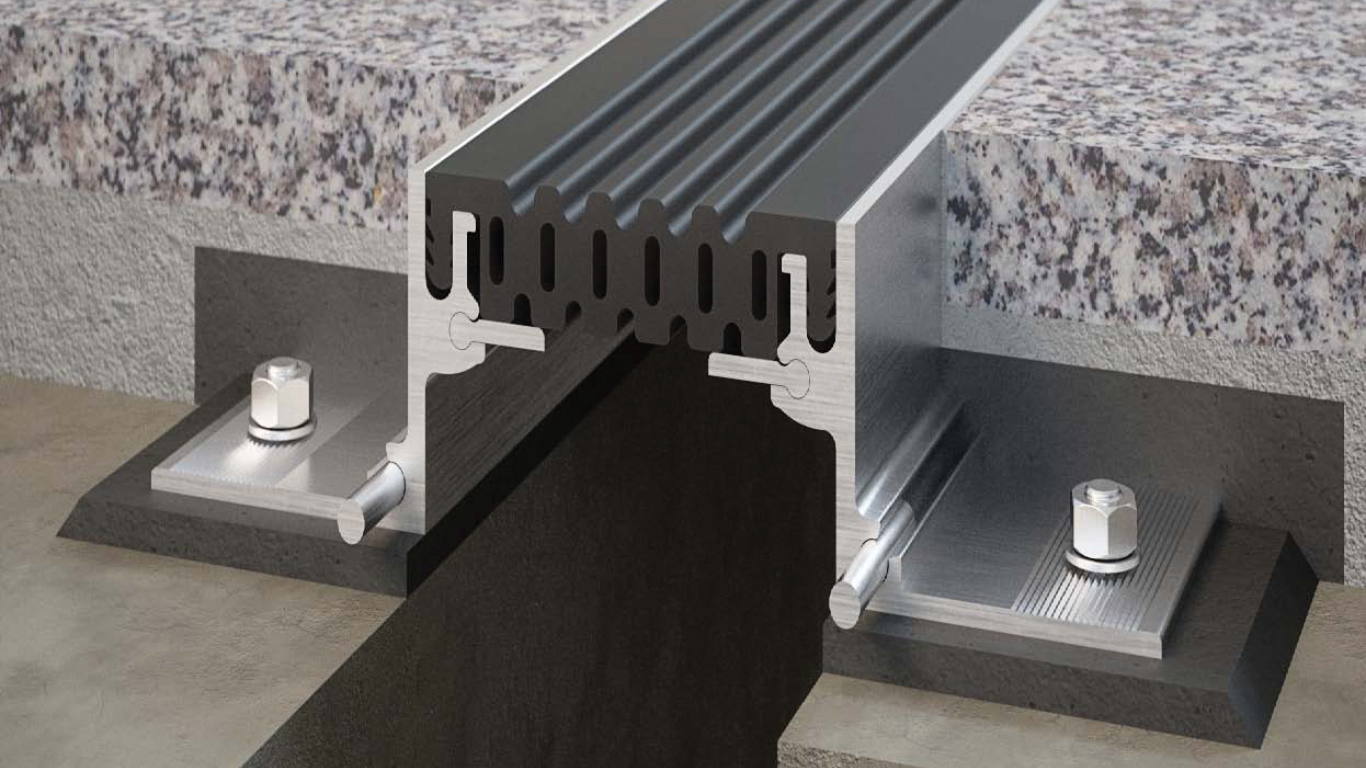

Understanding Expansion Joints

Expansion joints are designed gaps or spaces incorporated into structures to accommodate movement caused by thermal expansion, contraction, seismic activity, and other dynamic forces. They prevent cracks, buckling, and other forms of structural damage by allowing different parts of a structure to move independently.

Key Factors to Consider When Choosing Expansion Joints

Type of Structure

- The type of structure you’re working on significantly influences the choice of expansion joint. Buildings, bridges, pipelines, and other structures each have unique requirements.

- Building Expansion Joints: Used to divide large buildings into smaller sections, allowing for independent movement.

- Bridge Expansion Joints: Accommodate movements caused by temperature changes, traffic loads, and seismic activity.

- Pipeline Expansion Joints: Absorb thermal expansion and contraction in piping systems, reducing the risk of leaks and damage.

Material Compatibility

- The material of the expansion joint should be compatible with the structure and environment. Common materials include rubber, metal, and flexible polymers.

- Rubber: Offers flexibility and durability, suitable for a wide range of applications.

- Metal: Provides high strength and resistance to extreme temperatures, ideal for industrial and high-load applications.

- Flexible Polymers: Offer versatility and chemical resistance, suitable for various environmental conditions.

Environmental Conditions

- Consider the environmental conditions the expansion joint will be exposed to, including temperature fluctuations, moisture, chemical exposure, and UV radiation.

- Temperature Fluctuations: Select materials that can withstand the expected range of temperatures.

- Moisture and Chemical Exposure: Choose materials with resistance to moisture and chemicals if the joint will be exposed to these elements.

- UV Radiation: For outdoor applications, select UV-resistant materials to prevent degradation.

Movement Requirements

- Assess the expected range and type of movement, including thermal expansion, contraction, and seismic activity.

- Thermal Expansion and Contraction: Determine the amount of expansion and contraction expected and choose a joint that can accommodate this movement.

- Seismic Activity: In earthquake-prone areas, select expansion joints designed to absorb seismic forces.

Load and Pressure

- Consider the load and pressure the expansion joint will need to withstand, particularly in high-load applications such as bridges and industrial facilities.

- High-Load Applications: Choose joints with high strength and load-bearing capacity.

Installation and Maintenance

- Factor in the ease of installation and maintenance requirements for the expansion joint.

- Ease of Installation: Select joints that are straightforward to install, reducing labor costs and time.

- Maintenance Requirements: Consider joints that require minimal maintenance, ensuring long-term performance and reliability.

Steps to Choose the Right Expansion Joint

Identify the Application

- Determine the specific application and type of structure to ensure you choose an expansion joint that meets the project’s unique requirements.

Evaluate Environmental Conditions

- Assess the environmental conditions the joint will be exposed to, including temperature, moisture, chemicals, and UV radiation.

Determine Movement Requirements

- Calculate the expected range and type of movement, ensuring the expansion joint can accommodate these forces.

Select the Appropriate Material

- Choose a material that is compatible with the structure and environment, offering the necessary flexibility, durability, and resistance.

Consider Load and Pressure

- Ensure the expansion joint can withstand the load and pressure requirements of the application.

Plan for Installation and Maintenance

- Opt for joints that are easy to install and require minimal maintenance, ensuring long-term performance and cost-effectiveness.

Conclusion

Choosing the right expansion joint for your project is crucial for ensuring the structural integrity, safety, and longevity of your construction. By considering factors such as the type of structure, material compatibility, environmental conditions, movement requirements, load and pressure, and ease of installation and maintenance, you can select the ideal expansion joint for your needs. Making an informed decision helps prevent structural damage, reduces maintenance costs, and enhances the overall success of your project.