In modern construction and design, stainless steel (SS) divided strips are integral components used for a variety of purposes, including expansion control, aesthetic detailing, and joint separation. These strips come in different forms, with the most common being Type L and Type I. Each type serves specific functions depending on the application, offering flexibility, durability, and corrosion resistance. This article explores the benefits, characteristics, and uses of SS divided strips in both Type L and Type I configurations and how to choose the right one for your project.

What Are SS Divided Strips?

SS divided strips are thin, stainless steel bars or profiles used to divide surfaces, control movement, and ensure proper alignment between materials like tiles, concrete, or stone. These strips can be installed in flooring, walls, and ceilings to allow expansion, prevent cracks, and enhance visual design.

Because stainless steel is highly resistant to corrosion and rust, these strips are widely used in environments exposed to moisture, chemicals, or extreme temperatures, such as commercial kitchens, public buildings, and exterior facades.

Overview of SS Divided Strip Types: L & I

There are two common types of SS divided strips used in construction:

-

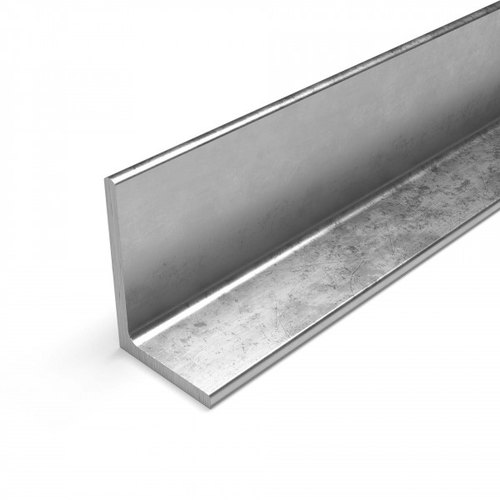

Type L SS Divided Strip: Shaped like the letter “L,” this type is primarily used for edge detailing, transitions between materials, and corner protection. The L-shaped design provides structural integrity and a clean finish where two surfaces meet.

-

Type I SS Divided Strip: Shaped like the letter “I,” this strip is often used for separating two different materials or tiles, as well as for providing movement joints. The I-shape is useful in flat surface applications and ensures that the transition between materials is even and visually appealing.

Benefits of Using SS Divided Strips in Construction

-

Corrosion Resistance

- One of the key benefits of stainless steel divided strips is their resistance to corrosion and rust, even in environments exposed to moisture or chemicals. This makes them ideal for both interior and exterior applications.

-

Durability

- Stainless steel is known for its strength and durability. SS divided strips can withstand heavy loads, impacts, and wear, ensuring a long lifespan in high-traffic areas like airports, hospitals, and malls.

-

Aesthetic Appeal

- SS divided strips provide a sleek, modern finish to surfaces, making them suitable for decorative purposes. They offer a clean, polished look that complements contemporary designs.

-

Flexibility and Versatility

- Both Type L and Type I divided strips are versatile, used in various applications, including expansion joints, surface division, and edge protection. They are compatible with a wide range of materials like tiles, wood, concrete, and stone.

-

Easy Installation and Maintenance

- SS divided strips are relatively easy to install and require minimal maintenance. Once installed, they only need occasional cleaning to maintain their appearance and functionality.

-

Thermal and Structural Movement Accommodation

- These strips are especially useful in areas where thermal expansion and contraction are common. The flexible properties of stainless steel allow for small movements without causing cracks or structural damage.

Type L SS Divided Strip: Key Applications

The Type L SS divided strip is widely used for corner detailing, edge protection, and transitions between different materials or surfaces. The L-shaped design makes it effective for securing and protecting edges in construction projects. Key applications include:

-

Tile Edge Protection

- In tiled surfaces, Type L strips are used to protect the exposed edges from damage and to provide a smooth transition between different surfaces. They also prevent tiles from chipping, making them ideal for kitchens, bathrooms, and commercial spaces.

-

Wall and Floor Transitions

- The L-shaped profile can be installed between walls and floors to create a seamless transition between different materials, such as tile and wood or concrete and tile. This provides both functional support and aesthetic enhancement.

-

Corner and Edge Reinforcement

- Type L strips are commonly used in areas where walls or tiles meet at a corner, reinforcing the structure and preventing cracks or damage from impacts.

-

Surface Termination

- Type L strips can be used to terminate the edges of surfaces, particularly where one material ends and another begins. This provides a clean, professional finish.

Type I SS Divided Strip: Key Applications

The Type I SS divided strip is commonly used for creating expansion joints, separating materials, and providing movement control. Its straight, I-shaped design makes it ideal for flat surface applications. Key uses include:

-

Movement Joints

- Type I strips are frequently used to create movement joints between tiles, concrete, or other materials. These joints allow for thermal expansion and contraction without causing cracks or damage, making them essential in environments exposed to temperature fluctuations.

-

Surface Division

- Type I strips are often installed between different materials, such as separating two types of tiles or creating a joint between concrete slabs. This division ensures even spacing and alignment, enhancing both the durability and appearance of the surface.

-

Flooring Transitions

- In large floor areas, Type I strips help create visual and functional transitions between different flooring materials, such as tile and stone, or wood and tile. This provides both structural integrity and aesthetic harmony.

-

Exterior Facades

- For exterior walls or facades, Type I SS divided strips are used to accommodate movement caused by environmental changes. They help prevent cracks in the facade, ensuring the structure’s longevity and appearance.

How to Choose Between Type L and Type I SS Divided Strips

-

Consider the Application

- If you need edge protection or corner reinforcement, Type L strips are the better choice. For surface division or movement joints, Type I strips offer better performance.

-

Material Compatibility

- Both types of SS divided strips work well with materials like tiles, stone, concrete, and wood. However, consider the material thickness and design when choosing the type of strip to ensure the best fit.

-

Aesthetic Considerations

- Stainless steel divided strips provide a sleek and modern finish. Choose the type that best aligns with the visual design of the space, whether you need clean transitions or subtle separation between materials.

-

Durability and Maintenance

- Both types offer the same level of durability and corrosion resistance. However, consider the installation environment when making your choice, especially in areas exposed to moisture, chemicals, or heavy traffic.

SS divided strips (Type L and Type I) are invaluable in modern construction for their ability to provide structural integrity, accommodate movement, and enhance the visual appeal of surfaces. Whether you’re looking for edge protection, movement joints, or surface division, these strips offer versatility, durability, and a sleek finish. Understanding the specific applications of Type L and Type I will help you choose the right option for your project, ensuring both functional and aesthetic success.